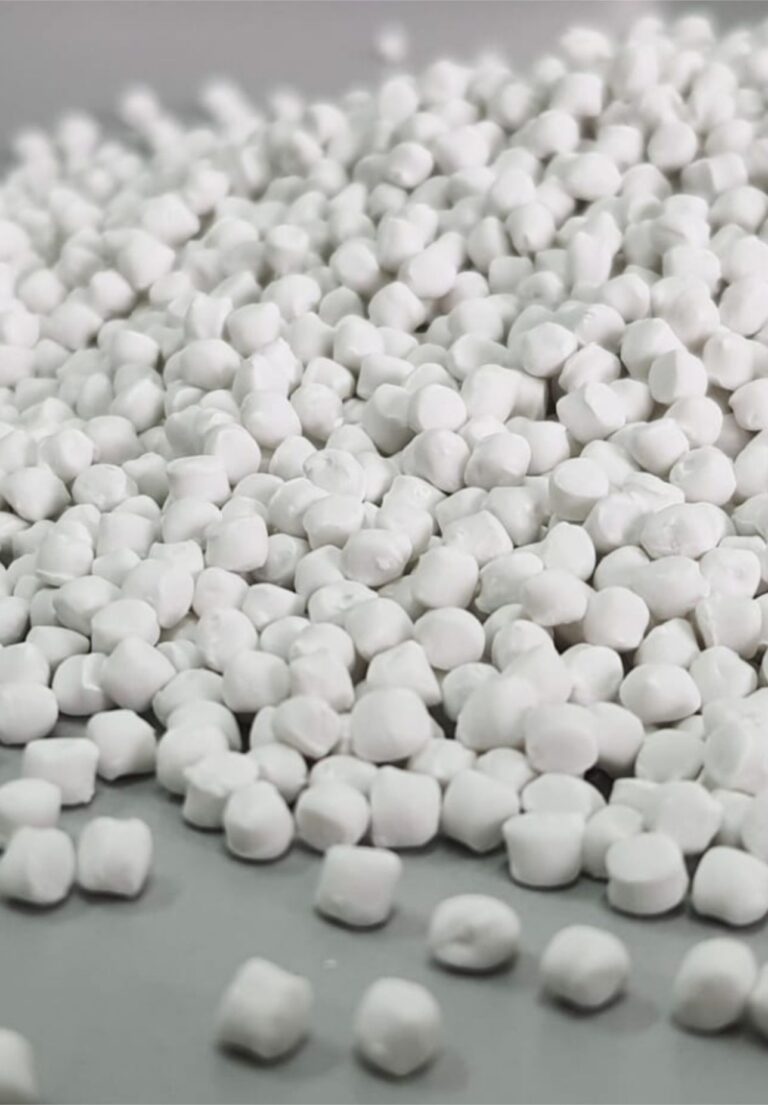

Sodium Sulphate is an inorganic compound which appears to be odorless and tasteless. It is a highly soluble compound in water as well as in glycerol but insoluble in ethanol. The Na2SO4 Filler MB is highly recommended for PE Packaging Films, shopping bags and all sorts of natural films except Stretch and Shrink Films. This is manufactured by blending PE as carrier resin with Sodium Sulphate and some additives. This results in excellent transparency, favorable glossiness and great tensile strength on the end products.

- Retains Transparency

- Imparts Glossiness

- Good Appearance Dispersibility

- Improves Mechanical Properties

- Maintains Good Film Break Strength

- Low Density

- Shock Resistance

- Acid and Alkali Resistance

- Environment Friendly

Explicab Filler

We manufacture Sodium Filler in multiple grades under the name Explicab Filler. There are mainly 3 grades of our Explicab Filler normally used. The results of these different grades can be seen below.

FCMB 1170 Explicab Filler – A 1

This is one of the prime materials in the Explicab Filler range. The sodium used is superior grade blended with several additives. This PE base filler is pure white in color and ensures excellent transparency even in high dosing. The film imparts glossiness and has a great film break strength. Certainly, warrants an acceptable cost cutting for the industries without compromising with the quality.

FCMB 1170 Explicab Filler – A 2

This is another regular grade in the Explicab Filler series. There is a slight change in the grade of sodium as used in Al and the additives dosing is reduced. The filler is white in color and ensures a good transparency in the films but slightly reduced than A1. This is also a decent grade with a reduced price. The transparency is lowered to a very shallow extent not majorly differentiable.

FCMB 1170 Explicab Filler – A 3

This is a cost-effective grade we are manufacturing in the Explicab Filler Series. The sodium used is noticeably different as used in other grades. The Filler is slightly dull in color and imparts satisfactory transparency in the film. This doesn’t mean that the filler can make the film opaque but the transparency is far lower than the high- end grades. Can be used in applications not requiring high accuracy in transparency and in the low micron films.

Prerequisite

It is very important to know regarding sodium Filler that this needs to be preheated before use. Since the base compound is Sodium which is highly prone to Moisture, PREHEAT is mandatory. The preheat will ensure the moisture removal from the filler and if not done the effects can be seen on the product hampering the transparency of the Film to a major extent. Suggested Preheat is in 70-80 Degrees for 8-10 minutes and during Monsoons or Industries in Coastal Areas need to increase the suggested preheat to some considerable extent. Industries with no provision of preheat can run the material in high-speed mixtures for ample time to remove the moisture from the Filler.

Dosing

The recommended Dosing of the Filler is between 3-35% depending on the degree of transparency required. It also depends on the grade of sodium filler being used as for the same dosing of filler the results will differ in all the three different grades of the Explicab Filler. The transparency will also change as per the thickness/micron of the film. While using the Explicab Filler in the same dosing the transparency of the film will increase as the thickness of the film reduces and the transparency will reduce as the thickness of the film increases.

Skepticism

There is to be noted that Sodium Filler is not to attain transparency but to RETAIN Transparency. It cannot make the translucent/opaque film transparent, rather it will retain the transparency of the Natural Films. This Filler is not recommended to use in PP Films. Any thing made with use of Reprocess material and Explicab Filler does not ensures any fair results. The results of this filler will be achieved only in use with Virgin material.